Recently on Cyclingnews.com |

Tech feature - May 10, 20052006 tech: SRAM empire unveils huge range, part 3Truvativ 2006: External bottom brackets and downhill beefThe most recently acquired part of the SRAM components empire is chainset maker Truvativ, which has itself expanded beyond its original mission as a maker of cranks and rings in recent years. In part 3 of our look at the SRAM empire's 2006 equipment, James Huang looks at what's new from SRAM's cranks arm. (Part 1 looked at 2006 RockShox and part 2 examined SRAM transmission parts.)

Micki Kozuschek founded Truvativ in 1996 with the hopes of providing small bike companies with a viable alternative to the dominant component suppliers of the time. Kozuschek started designing and building cranksets with a relatively meager US$160,000 initial investment but quickly landed some prominent OEM spec. Many of us remember seeing those mysterious cranks with the peculiar name popping up on bikes in the late 90's and wondering where they came from, but it's doubtful that people are still confused today. Since those early days, Truvativ (short for "truly innovative", by the way) has grown by leaps and bounds into one of the largest drivetrain and cockpit component companies in the business. Contrary to popular misconception, Truvativ is not a Taiwanese company. True, all of its components are produced in their manufacturing facility in Taiwan (which the company owns outright), but all other operations, including research, design, testing, and even advertising layout are done in-house at a relatively low-key facility in San Luis Obispo, CA.

First and foremost, Truvativ is a company of engineers. For example, head engineer, Garrett Smith was a stress analyst for Lockheed Martin Astronautics before joining Truvativ (not "aeronautics" - Smith can officially say that he was a rocket engineer!) All of Truvativ's bike parts, regardless of cost, are designed on a solid-modeling CAD system and every unique forging, casting, or machined bit is subject to finite-element stress analysis to fine tune the design. Truvativ even keeps a materials consultant on hand full-time to determine optimum alloys for particular applications. Only when the design is finalized are the drawings shipped off to the factory in Taiwan for production.

However, even when the parts come back, the design process is far from complete. Component testing is done in actual riding conditions, but the real interesting stuff happens behind closed doors in Truvativ's extensive in-house testing facility. Here, handlebars are brutally broken, cranks are bent, and bearings are cycled into oblivion, and the knowledge gained is integrated into some of the final components, which have a reputation for being durable and reliable. The weight-savvy out there will likely note that Truvativ's parts are often not the lightest, but chances are that the extra weight is there for a good reason. Truvativ has a number of key offerings for the 2006 model season. If you were to ask my parents, they would tell you that 2004 was the Year of the Rooster, but I will officially go on record as declaring the 2004 model year as the Year of the External Bottom Bracket. Sure, it wasn't the first time we'd seen the concept, but it was the first year it really hit the mainstream and it has only been a matter of time for all of the major players to jump on the bandwagon.

However, while externally-mounted bottom brackets have a number of advantages over conventional ones, they are not without their faults. Truvativ's version, dubbed Giga X Pipe, is a little different from its competition in that it automatically compensates for slight variations in bottom bracket shell width and facing. Truvativ accomplishes this with an design that comprises one "fixed" cartridge bearing and one "floating" bearing with automatic preload adjustment. The fixed bearing is designed just to handle radial loads while the other one handles radial loads and lateral loads (all other external BB setups currently on the market only handle radial loads). What's this mean to you? Think smoother spinning cranks and longer bearing life, which equates to going faster with less wasted energy and fewer trips to your local mechanic.

Giga X Pipe finds its way on to a bunch of Truvativ's cranksets for '06. The top of the road heap is occupied by the new Rouleur Carbon and features composite crankarms made up of a high-strength aluminum interior spine wrapped with high-modulus carbon fiber. The venerable aluminum Rouleur crankset, last year's top offering, is back and largely unchanged save for some cosmetic touches. The midlevel Elita crankset, however, has been completely revamped and now includes the Giga X Pipe external bottom bracket system. Both Rouleurs and the Elita are available in not only standard double and triple-chainring versions, but also compact and cyclocross-specific flavors. Cross-country mountain cranksets receive similar revisions for '06, including the addition of the Stylo Carbon utilizing similar carbon and aluminum hybrid construction as in the Rouleur Carbon. Last year's Stylo soldiers on while the midlevel Firex is upgraded to the GXP bottom bracket for '06. In refreshing contrast to some other makes, chainring options abound in Truvativ's off-road line: both Stylo variants and the Firex are available in both compact and standard drive, and the aluminum Stylo is even offered in singlespeed and double-plus-bashguard configurations.

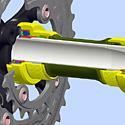

Downhill and freeride cranksets will receive extensive upgrades for '06 with the introduction of the Howitzer system. Truvativ has taken the external bottom bracket concept up a notch here with the addition of enormous cartridge bearings for greatly improved strength, stiffness, and bearing longevity. Designed around the new BB standard are the new Holzfeller and Hussefelt cranksets, as well as a new midlevel Ruktion model. As complements to these new cranksets, Truvativ will also release all-new single-chainring and double-chainring chainguides. What about the rest of Truvativ's line? Carbon is again the story of the day. A new Rouleur Carbon road handlebar will be offered in '06 with what are now industry de rigueur "aero" shaped tops and will mate to a new Rouleur 3D road stem, complete with a titanium bolt option. The Team Carbon seatpost is new for this year and will be offered in both a lightweight, offset single-bolt clamp and a new low-profile, zero-offset double-clamp. In keeping with Truvativ design tendencies, the Team Carbon posts will also be equipped with internal aluminum sleeves to provide some protection for those of you that still confuse in-lbs with N-m on your torque wrench. Other stems, posts, and handlebars have received revisions across the board, some of them minor and others less so. I'll be honest here, though… stems, seatposts, and handlebars really aren't all that exciting, and maybe for good reason. Personally, I'd rather take an unexciting version of one of those items that faithfully does its job without question vs. another one that may produce an "exciting" crash due to component failure. Based on those options, I'll take "boring" any day, and it looks like the folks at Truvativ have done their best to guarantee that your next ride be as uneventful as possible! Photography

James Huang is chief guru at mountain bike suspension site www.angryasian.com. |