|

|

|

|

|

|

|

|

Interbike show

Las Vegas, USA, September 26-30, 2005

Main Page Previous Part Next Part

Part 26 - Carbon, carbon everywhere… but will it fit?You're truly spoiled for choice if you want a carbon bike. But what if the available offerings don't quite fit you perfectly? James Huang looks at the companies offering a bike frame Holy Grail: custom carbon.

One of the most striking things about Interbike 2005 was that carbon fiber road frames were absolutely everywhere. Where once carbon fiber was considered ultra-exotic, nearly every major bike manufacturer these days (and many minor ones, too) had at least one carbon fiber road frame displayed in their lineup, and many had two or more distinct models. It comes as no surprise, though, as there are lots of reasons to like the stuff: it has fantastic strength- and stiffness-to-weight ratios and the ride characteristics can be finely tuned in a way that metallic materials typically can not be. However, if you're in the market for one of these high-tech gems, you may have also noticed that many models are only available in a limited size range and/or in size increments that are somewhat wider than the typical 2cm standard. So if you fall at one extreme in terms of sizing, are in-between available sizes, or your physiology simply lies outside of the norm, what are the options? The short and easy answer is to go custom, that is, until you consider the difficulties of doing such a thing with carbon fiber. For most metallic frames, going custom is often as easy (at least in theory) as adjusting the tube lengths and mitering angles then welding everything together as usual. Even lugged metallic frames have a pretty wide range of flexibility when it comes to varying angles and whatnot. However, carbon can't be welded, nor can it be brazed. Most carbon frames today are assembled using one or more of a handful of construction methods but almost all of them require a mountain of expensive tooling and custom molds. This is often the reason for those limited production sizes to begin with, but it's also why there aren't a heap of custom carbon builders around like there are with steel or aluminum frames. However, if custom is what you need, but carbon is what you seek, there are a small elite group of builders have taken on the challenge, including Parlee, Calfee, and Titus (well, sort of, but we'll get to that). More recently, the folks at Seven Cycles and Serotta also revealed their own fully custom, full carbon fiber road frames at Interbike 2005. Each has their own take on the issue, but all have come up with creative solutions to the problem of variable carbon fiber frame assembly. |

||||||

Parlee - tube-and-lug construction? Not really.Parlee is a relative newcomer to the carbon fiber road scene having been on the market only since 2000. However, Bob Parlee arrived at the party with highly-honed carbon fiber skills from his experience in the high-performance sailboat world and quickly built himself an enviable reputation in the bicycle world. Most recently, Tyler Hamilton won this year's Mount Washington Hillclimb on a custom-built Parlee Z3SL. Back in his early CSC days, Hamilton was also known to pilot a custom Parlee Z1 (painted with official bike sponsor graphics, of course) before being sponsored by the folks at Cervelo. Parlee's frames, at least superficially, use a tube-and-lug style of construction. However, instead of plugging tubes into pre-made lugs, the lugs are formed around the precision mitered and aligned carbon fiber tube joints. Carefully cut sheets of carbon fiber are laid in place by hand then the joint is cured in a mold under high heat and pressure to virtually eliminate voids and resin pockets. The result is an extremely clean joint and, according to Parlee, a more direct carbon-to-carbon bond that also produces a livelier feeling frame. Since molds are still involved, there is still a finite range of tube angles that can be accommodated, but Parlee has a number of molds available for each joint and head tube extensions are even available. Additionally, each mold can allow for up to ± 2° of angular variability so just about any reasonable geometry can be produced. |

||||||

Calfee - looks conventional, but still isn't!Craig Calfee may very well have been doing the custom carbon thing longer than anyone with roots dating back to the late 1980s with his original Carbonframes brand. Calfee's frames also appear to use a conventional tube-and-lug construction but, as with Parlee, looks can be deceiving. Here, the lugs are again formed only after the tubes are mitered and aligned, but Calfee uses a unique clamshell mold to apply pressure to the lug during the curing process which results in their trademark webbed appearance which contributes to the frame's rigidity. This laminated method of construction allows for ± 1° of angular freedom per mold, and multiple molds are available per joint to produce a wide range of custom geometries. Head tube and seat tube extensions are also available. For projects that fall outside of the adjustment range of their molds, Calfee also uses a handwrapping method of construction that requires no tooling. As with his laminated construction, the tubes are mitered and aligned but now they are handwrapped with long sections of carbon fiber using a technique Calfee has developed over a number of years. The joints are cured as with other methods, but there is no pressure mold applied. As such, careful carbon application is critical to minimize voids, but this tool-less technique can accommodate virtually any joint combination and is also used on Calfee's revered bamboo bikes. |

||||||

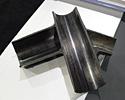

Titus: "TIG-welded" carbonAs already mentioned, you simply can not weld carbon fiber. You can, however, add some metal ends to a carbon tube and weld those. The concept isn't a new one: Diamond Back used chromoly ends in their Welded Carbon Fiber line of mountain bikes back in the early 90s. Fast forward to today, though, and find that the folks at Titus have joined forces with the whiz kids at Vyatek to produce a carbon and titanium hybrid tubeset that uses the same idea but in a vastly more advanced package. The center section of the hybrid tube is made up of a carbon fiber tube that is internally reinforced with a network of aramid and carbon ribs (sort of like old Columbus SLX tubing) in a configuration dubbed Isogrid. Sections of titanium tubing are positioned around each carbon end and the entire thing is cured together under intense pressure in a process called BiFusion to produce a single tube with a constant outer diameter and flush transitions between the two materials. And there you have it: a carbon fiber tube with weldable ends. Sure, it's not really a full carbon fiber frame, but if done properly, it should still yield most of the advantages of carbon fiber with maybe just a tad extra weight. In regards to the subject of custom geometry, however, the major benefit of this setup is that the geometry options are limited only by what sorts of titanium tube joints you can miter and weld, which is to say just about anything. So no, it's not full carbon fiber, but it does offer a mountain of flexibility that is perhaps matched only by Calfee's handwrapping method. |

||||||

Serotta builds a true tube-and-lug frameSerotta's brand-new full custom, full carbon Meivici road frame is a stunning piece with a combination of custom Reynolds carbon fiber tubes and multi-modulus carbon fiber lugs. Interestingly, Serotta's new carbon construction method is remarkably similar to an old classic one. Like a good lugged steel frame, the Meivici uses fully mitered tubes that are plugged into precisely fitting lugs. Only in this case, the tubes are custom made Reynolds carbon fiber and the lugs are pressure molded multi-modulus carbon fiber. Investment casting may have provided enough precision back then but, for its carbon fiber flagship, Serotta CNC-machines the inside of each lug and the outer surface of each tube end for a perfect fit. The machining not only ensures a good fit but it also allows for a few degrees of angular variability. Serotta also has a heap of different lugs to choose from which combines with the machining to provide a wealth of custom geometry options. Additionally, Serotta is one of few companies to use wholly separate upper and lower head tube lugs for their carbon frame. This affords them the ability to form a carbon head tube of just about any length for their custom customers. |

||||||

Seven Cycles travels its own roadWhoa. The new Seven Diamas is definitely a different animal from the other custom carbon frames available in the market. Seven is still pretty tightlipped on exactly how this thing is put together since their patent is still pending. They will say, though, that it does not use lugged construction and it obviously doesn't use conventionally shaped tubes. Whatever the construction method may be, they allegedly will be able to accommodate virtually any size or geometry. Why is the Diamas shaped like it is? Well, basically because it can be. Since carbon fiber's properties are uniquely tunable, Seven can go with a rather aerodynamic frame shape which can still be made pretty comfy by altering the fiber layup. We'll have to wait a bit for some more details, but this certainly is an intriguing addition to the custom carbon world. So of all of these choices, which one is best for you? Well, I'm not going to back myself into a corner by even attempting to answer that one outright. Each approach certainly has its merits and limitations, and each has its own associated aesthetic. Which one suits you best will largely depend on a number of things, including how far from standard your desired geometry is intended to be, what sort of ride characteristics you are going for, and of course, your budget. Oh, right, I guess I didn't mention that, now did I? Well, there's a reason for that: no one short of Bill Gates or the Sultan of Brunei would likely call any of these cheap. That's not to say that they don't provide good value, but when you consider that Serotta's Meivici is nearly $7000USD and it doesn't even include a fork, that's sure to influence your decision at least a little. Happy shopping. PhotographyFor a thumbnail gallery of these images, click here Images by James Huang/Cyclingnews

|