Which way to the Shimano factory?

Photo ©: James Huang

|

|

Shimano's line of road wheels

Photo ©: James Huang

|

|

Shimano wouldn't say how many wheels

Photo ©: James Huang

|

|

When we say 'hand built'

Photo ©: James Huang

|

|

Spokes are loaded, hubs are ready to go.

Photo ©: James Huang

|

|

A Shimano employee carefully mates the rim

Photo ©: James Huang

|

|

Ok, so builders have access

Photo ©: James Huang

|

|

Wheels are fully trued and tensioned by hand.

Photo ©: James Huang

|

|

The truing stands look low-tech

Photo ©: James Huang

|

|

Dial gages help builders achieve

Photo ©: James Huang

|

|

Spoke tensions are carefully measured…

Photo ©: James Huang

|

|

…and tensiometers are regularly calibrated.

Photo ©: James Huang

|

|

Each wheel is catalogued

Photo ©: James Huang

|

|

The Malaysia factory

Photo ©: James Huang

|

|

Where does this go?

Photo ©: James Huang

|

|

The Dura-Ace build room

Photo ©: James Huang

|

|

Chances are this area is just slightly cleaner

Photo ©: James Huang

|

|

Dura-Ace wheel builders

Photo ©: James Huang

|

|

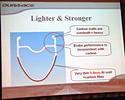

Shimano claims its C24 aluminum-and-carbon clincher rim

Photo ©: James Huang

|

|

Dura-Ace hubs are loaded up

Photo ©: James Huang

|

|

It looks confusing

Photo ©: James Huang

|

|

Dura-Ace spoke nipples

Photo ©: James Huang

|

|

A Dura-Ace wheel checking station

Photo ©: James Huang

|

|

The Dura-Ace wheel building stands

Photo ©: James Huang

|

|

A computerized station

Photo ©: James Huang

|

|